What is Fieldbus?

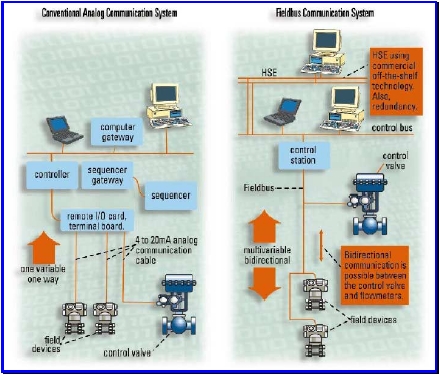

Field bus Foundation defines “Field bus is a digital, two-way, multi-drop communication link among intelligent

measurement and control devices.” It is one of several local area networks dedicated for industrial automation.

Modern industries could not survive without information technologies and networks in the 21st

century. From production line to enterprise level, digital communication supports all economical and social activities by

its latest and powerful technologies. Field bus is a part of it and cannot be

separated from others. Field bus is the lowest level in the hierarchy and exchange information with higher-level databases.

We have “standards” to transfer measurement and control data between control room and plant floor. They are pneumatic and

4-20mA electric signals. We have enjoyed their finest features of

Interoperability and easy maintenance. Smart communication introduced in mid 80’s opened an

era of digital communication, but it had many limitations such as proprietary protocols, slow

transmission speed and different data formats.

The idea of fieldbus was proposed to solve such problems. A “standardized” digital communication for industrial

automation is changing the production system very quickly.

Fieldbus Benefits

Fieldbus is expected to reduce the life-cycle cost of production line and then total cost of ownership (TCO) of the plant.

Planning Phase : Fieldbus allows you to integrate your plant assets on a single plant automation system on digital

communication networks. You can connect devices from multiple suppliers without custom

software and these network-based systems allow for smaller control rooms, smaller cabinet rooms and more

information productivity.

Installation Phase : Fieldbus offers reduced installation and material cost by replacing the traditional one-to-one

wiring scheme with networking or multi-drop configuration, while intelligent field instruments

make commissioning and plant startup much faster and less expensive.

Operation Phase : Fieldbus integrates various installations of control functions into one system to effectively

optimize control of your plant. In addition, a unified human-machine interface (HMI) is provided for your operation.

Function Blocks allow control functions to migrate into field devices allowing control functions to move to the field.

Maintenance Phase : Fieldbus allows for the reporting of self-diagnostics, calibration, and environmental conditions

of field instruments without disturbing the plant control. Since it uses intelligent instruments, your stock for spare or

replacement instruments can be dramatically reduced. Software packages for asset management are useful to minimize

maintenance costs.

Renovation Phase : Enhanced functionality of field instruments is endless. Fieldbus devices are becoming standard

off-the-shelf instruments, which make it very cost-effective and easy for you to extend the life of your plant. By simply

connecting a new device, you can immediately benefit from advanced functionality. And, upgrade costs can be reduced because

network-based systems are modular, which means they are done on-line.

FOUNDATION Fieldbus

Fieldbus is not a product but a technology to make above benefits available to end-users. The

following two conditions are necessary to make them come true:

- Many vendors provide fieldbus instruments.

- Those devices are interoperable

Fieldbus Foundation was established in 1994 to achieve these goals. Its major activities are

- To promote a single international fieldbus to both users and vendors,

- To deliver FOUNDATION fieldbus specification,

- To provide technologies for fieldbus implementation including education, and

- To install an infrastructure to achieve interoperability.

FOUNDATION fieldbus is a subset of IEC/ISA standard (IEC61158 and ISA s50.02). Fieldbus

Foundation and its members adopt FOUNDATION fieldbus as an enabling technology to utilize it to

bring the above benefits to end-users